|

Overview We are going to build a box with PCB soldered

permanently inside by it's rims. The box is made of metal and is closed with a

lid from both sides. The mounting barrels in the pictures are obsolete, now

there are mounting brackets. |

|

|

|

|

Handmade box

If you don't have factory-made box, make two lids and two

drilled strips of tin according to this

template. |

|

|

|

|

Factory box template

If you have a factory made box print out this drilling template. |

|

|

|

|

Factory box drilling If you have a

factory box, drill it out, according to the drawing and the factory box

drilling template which you glue on. Note: no barrels should be present

in any of the pictures in this box. One template in the pictures is missing

the 3.3mm holes. |

|

|

|

-e

|

Bracket Template If you plan to

build optical head and the pipe has diameter less than 105mm, skip this box and

the next one. Subtract box width (normally 92mm) from the optical head's pipe

inner diameter. If you don't plan to build optical head, assume 145mm.

Select the template according to the resulting number from the Side template list and print it. The template

is for two boxes, you need just half of it. |

|

|

Make the brackets

- Drill the side template out and bend it. Wash the template off in warm

water.

- Solder the M4 nuts over the holes from the inside.

|

|

|

|

Soldering board into case

- Watch the drawing how is the case and board assembled and oriented

- Remember solder side of the board will be 5mm deep in the box

- If you have handmade box, shape the two strips of metal around the PCB,

solder and cut the excess. Otherwise trim the PCB size by file until it

fits into the box.

- Solder the board to the box continuously along the edges

|

|

|

|

|

Solder on brackets/nuts

If you have brackets, then solder the brackets to the case, otherwise solder bare

M4 nuts from the outer side over the 4mm holes. |

|

|

![Gallery[1b4f]](http://images.twibright.com/tns/lvl2/1b4f.jpg)

|

Contact flaps

- Please note that the barrels in the picture are obsolete, there

should be mounting brackets.

- Make contact flaps

on both lids of the case using tin cutters.

- Adjust their angle by pliers so

that every flap is sprung against the case when the lid is closed.

- If not already done, cut away the flaps around the small hole for regulator (as seen in

the big picture).

|

|

|

|

|

M3 bolts

Install 2 M3 bolts and 4 M3 nuts as in the picture. Tighten. |

|

|

![Gallery[13fc]](http://images.twibright.com/tns/lvl2/13fc.jpg)

|

Making the coil

Take the 8.5mm bit and wind a 10-turn coil on it from the insulated

1mm^2 hard copper wire.

![Gallery[13fd]](http://images.twibright.com/tns/lvl1/13fd.jpg) |

|

|

Part lists

Print one part list from these according to your storage method. It will be used during population of the

PCB:

|

|

Warning: fopen(../schematics/metropolis_transmitter/metropolis_transmitter.pcb.output_assembly.php): failed to open stream: No such file or directory in /home/clock/www/twibright.com/ronja/boxed_page.php on line 103

Warning: filesize(): stat failed for ../schematics/metropolis_transmitter/metropolis_transmitter.pcb.output_assembly.php in /home/clock/www/twibright.com/ronja/boxed_page.php on line 104

Warning: fread() expects parameter 1 to be resource, boolean given in /home/clock/www/twibright.com/ronja/boxed_page.php on line 104

Warning: fclose() expects parameter 1 to be resource, boolean given in /home/clock/www/twibright.com/ronja/boxed_page.php on line 105

|

|

Populating

Print out this assembly plan. Populate the board in this order:

- Resistors except R12-R16 (those are not on the board)

- Diode (not LED)

- All IC's except U4

- Electrolytic capacitors

- Capacitors

- Transistors

- Coil

|

|

|

![Gallery[1b5b]](http://images.twibright.com/tns/lvl2/1b5b.jpg)

|

Installing regulator

Material:

- 1pc. bolt M3x6, galvanized, hex or Allen or Philips or cheese head

- 1pc.. nut M3, galvanized

- 1pc. toothed spring washer M3 (3.2mm), galvanized

Install the 7805 regulator according to the photos. Place thermal paste between

the regulator and case for good thermal contact. |

|

|

|

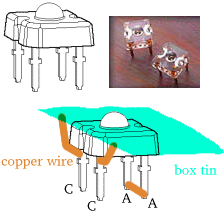

Transmitter LEDPut the HPWT-BD00-F4000 LED

into the 3mm hole in front of transmitter case and solder cathode (C) directly

to the round pad on the PCB. Solder anode (A) with short pieces of 1mm^2 wire

to the square pad. Solder cathode (C) with another pair of wires to the metal

box. These wires, besides grounding, will conduct heat and cool the

LED. |

|

|

Correctness check

- Check that all IOs, diodes, transistors and polarized capacitors are

oriented the right way.

- Check that all IOs and transistors are the right type.

- Check that no component is missing

- Correct values of components

- That cables are soldered on the right pad

|

|

|

WarningWhat do you think would happen if you skip this correctness

check? "Your board would come to a screeching halt and you'd fly.

And you'd smash cement." -- Stacy Peralta, Dogtown and Z-Boys" |

|

|

|

|

Stripping

- Take 20cm stranded

double-conductor cord 1.5mm^2 and 20cm shielded stranded single-conductor with

solderable shield.

- Strip 4mm of insulation from the unshielded cable on one sides.

- Strip 29mm

of the outer insulation from the shielded cable on one side. Strip 4mm of the

inner insulation from the shielded cable on one sides.

- Cover all bare ends with solder.

|

|

|

|

|

Copper stubs

Solder 4 copper stubs made from 4mm^2 uninsulated hard

copper wire on stripped ends of both conductors.

|

|

|

|

|

Colour insulation

- Insulate the stubs with colour duct tapes according to the diagram.

- Strip remaining ends of the unshielded cable in 4mm length

- Strip shielding from remaining end of coaxial cable in 10mm length

and the inner wire in 3mm length

![Gallery[1b6a]](http://images.twibright.com/tns/lvl1/1b6a.jpg) |

|

|

|

|

Installing wires

Install the wires, solder them inside to square soldering pads and fix

them in the hole from both sides by fair amount of thermal glue or silicon

putty. |

|

|

![Gallery[1b7d]](http://images.twibright.com/tns/lvl2/1b7d.jpg)

|

Washing and inspection

Wash the device in isopropyl alcohol. Store the dirty isopropyl alcohol for

re-use as pre-wash for other boards. Inspect all soldered places that they

do not contain cracks or shorts and their surface is not wrinkled. Repair

those that are bad by re-melting with rosin flux. |

|

|

Small schematic

Print out the schematic on a piece of paper size 90x60mm. Overwrite all part

numbers that have been installed different than in schematic. Overwrite all

resistor values that have been chaged during tuning. Write down amplification

factors of both 2N3904 transistors. Glue the paper on the inner side of the

lid. |

|

|

|

Labelling

Print out the Ronja 10M Metropolis Transmitter label.

Fill in and glue on the

outer side of one lid.

|

|

|

![Gallery[1b81]](http://images.twibright.com/tns/lvl2/1b81.jpg)

|

Closing

Close the lid without label on the side near circuit board. Try to close on the

other lid. If the regulator bolt head is in the way, cut out a notch in the lid

flaps using tin shears, then close. |

|

|

M4 bolts

Screw the M4x8 bolts into barrels. Your transmitter is now ready. |

|

|

|

Schematics

Not needed for building - just for completeness. |

|

|