![Gallery[13e9]](http://images.twibright.com/tns/lvl2/13e9.jpg) |  | Overall view

We are going to build a holder: | |

|

|

Quoin template If you

have exact printer, print out these three templates and glue the appropriate

one on your 100x100 steel section.

Expanded quoin templates

|

|

|

|

|

Aiming Gauge

- If you have accurate printer, print out this template, glue on a tin, and

cut or chisel out.

- If not, measure the gauge manually. The number indicate width of the

part in millimeters.

|

|

|

|

Purpose of aiming gauge

- It is for checking minimum, maximum and starting compression of the rubber

aiming blocks.

- Lead of the M8 screw is 1.25mm. The useful range is 6mm or 4.8 turns.

|

|

|

|

|

|

|

Plate template

- If you have accurate printer, print out this template, otherwise jump to

the next box ("Drill out the plate").

- The template is for 4 identical plates, you need only one for a holder

- The gap between the templates is suitable for a saw, too.

- Cut out the template and glue on the 90x8(10,12) flat steel

|

|

|

|

|

|

|

Blocks template

- If you have accurate printer, print out this template, otherwise jump to

the next box ("Drill out the plate").

- The template is for 4 identical plate block and 4 identical cross blocks,

you need only of each for a holder.

- The gap between the templates is suitable for a saw.

- Cut out the template and glue on the 25x25 square bar

![Gallery[1ce5]](http://images.twibright.com/tns/lvl1/1ce5.jpg) |

|

|

|

|

Drill out the cross and plate blocks. |

|

|

![Gallery[1318]](http://images.twibright.com/tns/lvl2/1318.jpg)

|

Rubber block drilling

Drill 8.5mm hole in each rubber block excentrically,

with center 10mm from the edge. Use 9.5mm or so drill bit.

|

|

|

|

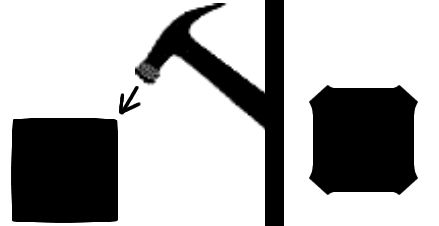

Bang the blocks with a big hammer along the edges to bulge them out to cancel

out possible convexity of the sides.

|

|

|

Grinding burrs Grind the area around holes with emery

paper flat so that there are no burrs (they could creep under the bolt preload

with time). |

|

|

Parts to be washed and painted

- Quoin

- Plate

- Cross block

- Plate block

|

|

|

Cleaning

- Fill a bucket with hot water and add detergent, for dosage see the bottle

label

- Throw all pieces with templates into the bucket and let the templates soak

off.

-

Use emery paper to remove noncohesive rust from pieces

where templates weren't used.

- Wash parts to be washed plus parts already in water in the bucket using

a brush or sponge to get rid of all grease

- Place everything wet on a rag and dry with hairdrier while turning

around.

- Now remove noncohesive rust from pieces where templates were used.

|

|

|

|

Critical zones

Critical zones for Plate are on the picture (from both sides).

The remaining pieces have them:

- plate block where plate will be attached (8.5mm holes)

- plate block where cross block will be attached (10.5mm holes)

- cross block where plate block will be attached (10.5mm holes)

- cross block where console will be attached (10.5mm holes)

- quoin where heel will be attached (6.5mm holes)

- quoin from inner side around the four 8.5mm holes

|

|

|

|

|

|

|

Assembly

Assemble the holder. Mirroring is insignificant (the holder can be

cofigured to accomodate particular situation). The 3D model shows

intermediate stage of assembly, the photo final assembly.

![Gallery[13e9]](http://images.twibright.com/tns/lvl2/13e9.jpg) |

|

|

Accessories

Keep the rubber blocks, 3 M8x50 bolts

and 3 M8 jam nuts for future mounting.

|

|