|

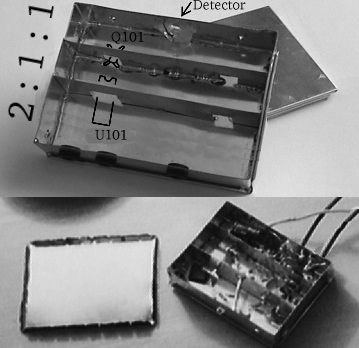

OverviewWe are going to build a tin box with lid here. Box

will be equipped with mounting brackets and wire leads. Finally we'll

solder receiver electronics inside. The result without the lid will look like

this except for mounting brackets: |

|

|

|

|

|

-e

|

Bracket Template If you plan to

build optical head and the pipe has diameter less than 105mm, skip this box and

the next one. Subtract box width (normally 92mm) from the optical head's pipe

inner diameter. If you don't plan to build optical head, assume 145mm.

Select the template according to the resulting number from the Side template list and print it. The template

is for two boxes, you need just half of it. |

|

|

Make the brackets

- Drill the side template out and bend it. Wash the template off in warm

water.

- Solder the M4 nuts over the holes from the inside.

|

|

|

Main box

Note the picture shows an older type of the box.

- Glue the box template on tinned steel plate.

- Cut and drill out.

- Bump the indicated points.

- Bend into a box shape.

- Remove the template with warm water

- Solder the corners up

- Solder the partitions (strips with square notches)

inside the box. The strip positions are given by the bumps on the bottom.

Solder all along

their gap, not just in several points.

![Gallery[167]](http://images.twibright.com/tns/lvl1/167.jpg) |

|

|

Solder on brackets/nuts

If you have brackets, then solder the brackets to the case, otherwise solder bare

M4 nuts from the outer side over the 4mm holes. |

|

|

DetectorPut the BPW43 or SFH203 detector into the 5mm hole in the

case and solder anode to the

box. The Anode (A, the longer pin) is described in the lower left

corner of the schematic (below). When inserting the detector into the hole, make

sure the detector is perpendicular to the plane (is not askew) and about 1/3 of

the plastic body is protruding out. The chip must be inside otherwise catches

intereference! After soldering, fix it from the inner side using the

thermal glue gun (optional, recommended). |

|

|

![Gallery[164]](http://images.twibright.com/tns/lvl2/164.jpg)

|

Grommet

Put the cable grommets into the 8mm holes. Note: the box in the picture should

have mounting brackets soldered on. |

|

|

Cutting cables

Cut the following types and lengths of cables:

| Qty | Type | Length

| | 3 | shielded single-conductor | 20cm

| |

|

|

|

Stripping

Strip 29mm

of the outer insulation from the shielded cable on both sides. Strip 4mm of the

inner insulation from the shielded cable on both sides.

Cover all bare ends with solder. |

|

|

|

|

Installing

cable leads Put the bare ends through the grommets as seen in the picture.

Leave the middle cable's shield unconnected but solder the remaining shields to

the box. Seal the cables inside the grommets with sillicone sealant (you can

also use thermal glue, it is faster). Seal from both inside and outside of the

grommets. When sealing the outside take care not to occupy the place where the

lid will be (the rim of the box). |

|

|

|

|

Copper stubs

The cables ends that are not inserted into the box need copper stubs.

Solder 6 stubs made from 4mm^2 uninsulated solid copper wire. |

|

|

|

|

Colour insulation

Insulate the stubs with colour duct tapes according to the diagram. |

|

|

Making the coilTake the 8.5mm bit bit and wind a 10-turn coil on it from the

insulated1mm^2 hard copper wire. |

|

|

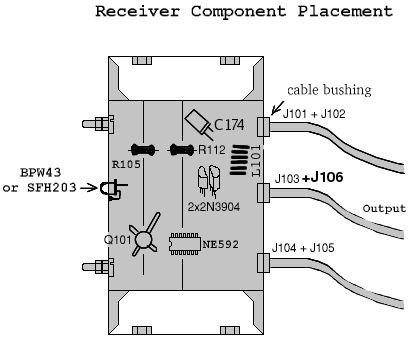

Key componentsPlace some important components into the box according to the drawing. Fix them

by soldering on their ground lead. If they don't have any ground lead and you mind them rolling all around inside the box, you

can glue them down using thermal glue gun. |

|

|

|

We are going to place components according to a schematic. There are arrows in the schematic labeled "P*" where "*" varies. They don't mean any component, they are just test points. |

|

|

|

Stereo pictureYou can view a stereo picture of populated RX to get a notion how

the components are mounted inside prior to starting soldering them down. Please

note there should be mounting brackets instead of the screws:

![Gallery[d39]](http://images.twibright.com/tns/lvl1/d39.jpg) |

|

|

|

Now the following components are already installed in the

box:

|

|

|

|

|

Place the remaining components

according to the schematic in this sequence:

- C168 close to J101

- C165 close to J101

- C178 close to J103

- C179 close to J103

- C163 close to U101

- C164 close to U101

- C154 close to Q101

- C153 close to Q101

- L102

- R101

- C173

- C167

- D101

- R103

- C152

- C161

- C155

- C151

- C177

- C175

- L101

- R122

- C172

- D103

- C162

- C157

- D102

|

- R102

- R104

- C156

- R111

- R113

- R108

- R109

- R110

- R115

- C158

- C166

- R117

- R120

- R119

- R107

- C169

- R116

- R121

- C178

- R114

- R118

- C160

- C170

- C159

- C171

|

|

|

|

Correctness check

Take the schematic and a multimeter and check everything except

R106 (still missing). Check that the

topology is OK (i. e. the wires lead where they should lead). Measure every

resistor with a multimeter (sometimes it will show less if there is a current

path around). Check every capacitor visually where the value is visible.

Check every diode and transistor junction with diode measuring function of

the multimeter. Scrawl out every part and wire you check on the schematic

with a pencil. Check visually all soldered joints for quality and resolder

all joints where suspicion may arise. |

|

R106

Connect 12V regulated supply: + to J101 (red) and - to J102 (black).

Set multimeter to 200mA and put red probe to P104A and black probe to

P104. Measure current.

Disconnect from power. Select R106 according to this table:

| Current [mA] | R106 [Ohm]

|

|---|

| 3-3.6 | 1.8k |

| 3.6-4.4 | 1.5k |

| 4.4-5.5 | 1.2k |

| 5.5-6.5 | 1k |

| 6.5-8 | 820 |

| 8-10 | 680 |

| 10-12 | 560 |

| 12-14 | 470 |

| 14-17 | 390 |

| 17-20 | 330 |

| 20-24 | 270 |

| 24-30 | 220 |

| 30-36 | 180 |

Solder the R106 into the receiver. |

|

Schematic inside the lid

Print the small schematic (see above). Overwrite all part numbers that have been installed different than in schematic. Overwrite all resistor values that have been changed during tuning. Write down amplification factors of both 2N3904 transistors. Glue the paper on the inner side of the lid. |

|

|

|

Label

Print out the Ronja 10M Receiver label. Fill in the label and stick on the

outer side of the lid. |

|

|

Washers and nuts

Save the 4 M4 washers and 4 M4 nuts for future mounting. |

|