| Cut (115mm+focus) long piece from the 100mm smoke pipe using a hand saw |

|

|

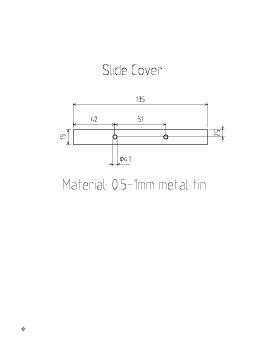

Cut and drill two slide covers |

|

|

|

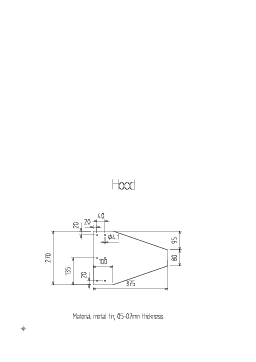

Cut and drill the hood. Bend the tin into![Gallery[56e]](http://images.twibright.com/tns/lvl2/56e.jpg) this shape. this shape. |

|

|

|

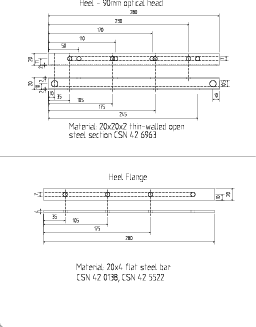

Drill out the steel sections for the heel |

|

|

|

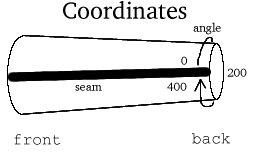

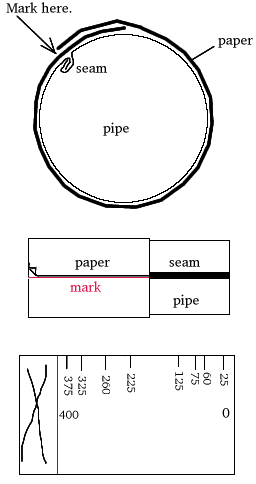

Mark the wider end of the pipe as front and the narrower one

as back. In the next, we will describe coordinates on a cylinder - by angle and

length from one edge. Angle is in grads - 400 grads form complete circle. |

|

|

|

Use a sheet of paper wrapped around to measure the angle.

Wrap the paper around

and make a circumference mark where the edge is. Then put the paper on

desk and divide the circumference by 400 using a calculator and make marks at 25, 75, 125,

175, 225, 275, 325, and 375 times this distance. Mark them 25grad,

75grad, 125grad, 175grad, 225grad, 275grad, 325grad, and 375grad.

Wrap the paper around the pipe again, the seam of the paper on the seam of the

tube, and copy the marks from the paper onto the tube as necessary. |

|

|

Mark and drill these holes on the pipe:

| Angle | Axial Offset | Hole

diameter | Purpose of the hole |

| 75grad | 11mm from front | 4.3mm | Holds

front cap |

| 175grad | 11mm from front | 4.3mm | Holds

front cap |

| 275grad | 11mm from front | 4.3mm | Holds

front cap |

| 375grad | 11mm from front | 4.3mm | Holds

front cap |

| 75grad | 11mm from back | self-cutting screw predrill diameter | Holds

rear cap |

| 175grad | 11mm from back | self-cutting screw predrill diameter | Holds rear cap |

| 275grad | 11mm from back | self-cutting screw predrill diameter | Holds rear cap |

| 375grad | 11mm from back | self-cutting screw predrill diameter | Holds rear cap |

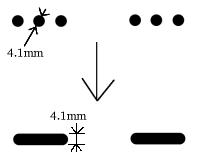

| 125grad | (focus-20mm) from front | 4.1mm | slide path |

| 325grad | (focus-20mm) from front | 4.1mm | Slide path |

| 125grad, | focus from front | 4.1mm | Slide path |

| 325grad | focus from front | 4.1mm | Slide path |

| 125grad | (focus+20mm) from front | 4.1mm | Slide path |

| 325grad | (focus+20mm) from front | 4.1mm | Slide path |

| 125grad | (focus+31mm) from front | 4.1mm | Slide path |

| 325grad | (focus+31mm) from front | 4.1mm | Slide path |

| 125grad | (focus+51mm) from front | 4.1mm | Slide path |

| 325grad | (focus+51mm) from front | 4.1mm | Slide path |

| 125grad | (focus+71mm) from front | 4.1mm | Slide path |

| 325grad | (focus+71mm) from front | 4.1mm | Slide path |

| 25grad | 55mm from front | 7.0mm | heel |

| 25grad | 125mm from front | 7.0mm | heel |

| 25grad | 195mm from front | 7.0mm | heel |

| 25grad | 265mm from front | 7.0mm | heel |

| 225grad | 40mm from front | 4.3mm | hood |

| 225grad | 80mm from front | 4.3mm | hood |

|

|

|

Connect holes

in each group of three holes marked for future sliding path together to

form a sliding path for the screws. Use a tiny file or fret-saw to

accomplish this. You can also horizontally vice an iron bar or pipe, and chisel the paths

out against it. |

|

|

|

In the next steps, we will manufacture these two caps: front and rear. |

|

|

Drilling front cap rim

- Take one cap and mark it as front.

- Insert it into the front of the pipe,

cap seam at 200 grad.

If it won't go, cut V-shaped slits into the rim at 25, 125, 225, 325 grad.

- Drill through

one 4.3mm hole with 4.3mm bit. Insert some M4 bolt and drill the hole on the

opposite side. Do the remaining three holes and always insert a bolt.

- Mark which side of the front cap is down (at the heel) with a permanent marker.

Remove the bolts and the front cap.

|

|

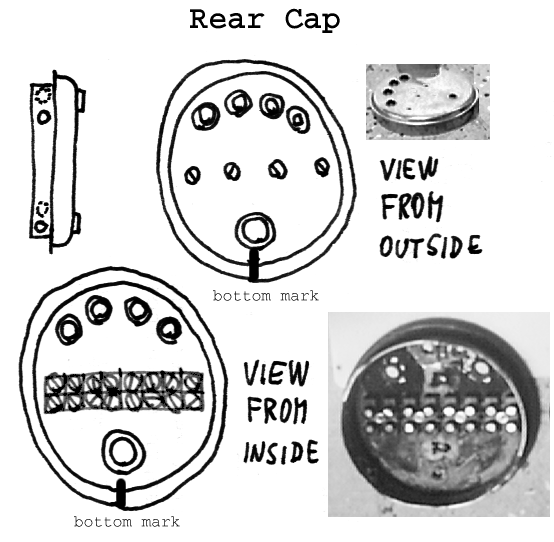

Drilling rear cap rim

- Take the other cap and mark it as rear.

- Insert it into the rear of the

pipe, cap seam at 200 grad. If it won't go, cut V-shaped slits into the rim

at 25grad, 125grad, 225grad, 325grad.

- Drill through one self-cutting screw predrill hole and insert some pin or

nail to keep it in place. Do the remaining three holes, inserting a pin or nail

every time.

- Mark a bottom mark on the cap at the heel holes.

- Remove the pins/nails and the rear cap.

- Drill through the four holes

at the rear of the pipe with self-cutting screw through-hole diameter.

|

|

|

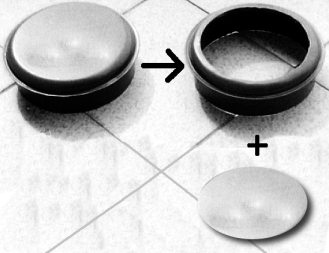

Cutting out front cap: Option 1 (handwork)Take the front cap. Make a mark in the center of the outer side using the

hard stylus and hammer. Measure exactly the lens diameter with slide gauge. Set pair of

compasses to (lens diameter/2)-1.5mm. Draw a circle. Make the circle more visible by

redrawing it using the marker pen. Put a block of wood vertically into a vice and the

cap over it, the rim down. Use cold chisel and hammer to chisel out the

curve. Then the round piece will fall out. Collect it, it will be the so

called thermal shield. Use the hammer to repair the face of the cut on the

wooden block. |

|

|

![Gallery[d5b]](http://images.twibright.com/tns/lvl2/d5b.jpg)

|

Cutting out front cap: option 2 (mechanized) Take

the front caps and mark the inside center of them with a marker. Take a nail

and with a slight strike mark the center with it (you may even drill there a

2-3mm hole). Set the pair of compasses to (lens diameter/2)-1.5mm and draw a

circle. Mount a jig saw on the underside of a wooden board, so the blade would

come out of the top of it. Take the cap and drill 3 to 5 holes (depending on

your blade dimension) on the circumference of drawn circle. Put the cap on the

board so the blade would poke through drilled holes. Adjust the position of the

cap, so its marked center would be ortogonal to the natural path of the jig saw

on the beginning of the blade. Now take a nail and hammer it through the center

of cap deep into the wooden board. Nip off the nail header, so you can remove

the cutting (future thermal shield) easily. Turn the saw on and pivot the cap.

When the hole for the lense is complete, clean the impurities with a hand

file. |

|

|

|

Finishing rear cap drillingPlace a 8-terminal wire nut on outer surface of the rear cap in position shown

shown in the drawing. Drill a 3.1mm hole between terminals 1 and 2, insert

an M3 bolt, drill a 3.1mm hole between terminals 7 and 8, insert a bolt,

and do another two holes between terminals 2 and 3 and terminals 4 and 5.

Drill one 8.5mm hole above the wire nut and four

10.5mm under the wire nut. |

|

|

|

|

Making thermal shieldDrill out the thermal shield as in the drawing. |

|

|

|

|

Silicagel boxes

- Print out these 8 templates and Cut out 4 of them.

Glue them on 67x46mm boxes lids

(leave lids on boxes).

- Punch all unmarked holes with an awl and drill out the 4.3mm holes

|

|

|

|

Parts to be washed

- Pipes

- Caps (front, rear)

- Heel, heel flange

- Thermal shield

- Slide covers

- Hoods

- Lenses

|

|

|

Cleaning

- Fill a bucket with hot water and add detergent, for dosage see the bottle

label

- Throw all pieces with templates into the bucket and let the templates soak

off.

-

Use emery paper to remove noncohesive rust from pieces

where templates weren't used.

- Wash parts to be washed plus parts already in water in the bucket using

a brush or sponge to get rid of all grease

- Place everything wet on a rag and dry with hairdrier while turning

around.

- Now remove noncohesive rust from pieces where templates were used.

|

|

|

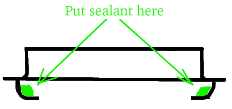

Preparing sealant for the lensPlace a fair amount of the sealant

inside front cap into the corner but not on the edge on which the lens will

sit. |

|

|

|

Sealing

lensPut the lens into the place from inside the cap and shape and finish

the sealant in many gentle circular motions with your little finger so that it

becomes smooth and flawless. Take a great care not to smudge the lens. If you

have smudged the lens and decreased clear aperture, wait until the sealant

partly solidifies and then remove it mechanically and clean the remaining haze

with a rag and acetone. Removing the hardened selalant is not easy and must be

done using a razor blade, without scratching the lens. |

|

|

|

Sealing the soft grommetsPut the soft grommets into the holes in rear caps:

6mm grommets into 8mm holes and 8mm grommets into 10mm holes. Seal them all

against the cap from both sides with the sillicone sealant. |

|

|

|

WarningIf you don't seal the optical head properly, water will probably

get inside. The link may stop working and the electronics may be irreparably

destroyed. See a video. |

|

|

|

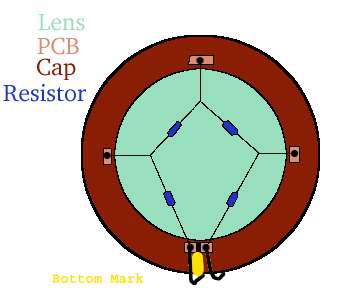

Installing

heating networkWait until the sealant solidifies on front cap. Cut four

small pieces of PCB blank and cut the copper on one side of one piece into two

pieces insulated by a gap. Solder these pieces regularly on the outer rim of

the lens, on the tin. Solder the 8.2-ohm resistors there as specified in the

drawing, connecting them to the rim with pieces of thin bare wire. Check that

there is no short circuit between the network and the metallic cap itself using

a multimeter. Wash the cap again with detergent, warm water and dry them into

the clean dry rag. Cut two pieces of two-conductor 1.5mm^2 insulated cord,

0.41m long. Solder two one-inch pieces of 4mm^2 hard copper wire on one end of

the cable and insulate the solder joints with duct tape. Solder the other end

of the cord one on the terminals of the heating network. |

|

|

|

Warning

Failure to paint the optical heads correctly can result in peeling of the

paint under the silicon sealant and water getting into the pipe, which will render

the link inoperable and destroy the electronics. See

a video. |

|

|

Painting with primer Paint with water-soluble primer.

Paint only those parts of the specified list which are able to corrode, i. e.

they are from raw steel or iron and are not galvanized nor tin-plated. Paint

caps, pipes (including inner surface), hoods, slide covers, and thermal shields

with water-soluble primer. Adhere to Amanufacturer's datasheet for recommended

procedure. |

|

Painting blackPaint with water-soluble matte black top

coat. Paint inner sides of the tubes, inner sides of the caps, inner sides of

the hoods, and the thermal shield. Adhere to manufacturer's datasheet for

recommended procedure. |

|

Painting whitePaint all remaining surfaces that are not

already black (including those that do not corrode) with the water soluble

white (matte or glossy) top coat. Paint caps, pipes, hoods, and slide covers.

Adhere to manufacturer's datasheet for recommended procedure. |

|

Removing paint from holes

Prick out paint from all holes. |

|

|

Installing wire nutScrew the 8-terminal wire nuts into itsn

apropriate places using the M3x15 screws, M3 nuts, and M3 washers. |

|

|

|

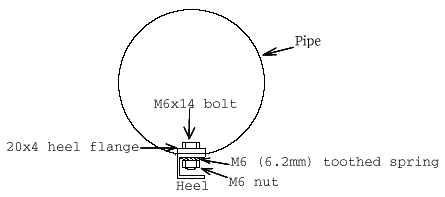

Attaching heelAttach heel to the pipe using 4 M6x14 bolts, 4 M6

(6.2mm) toothed spring washers and 4 M6 nuts. Tighten firmly. Seal with

silicone sealant: around bolt heads, around the 20x4mm flange, around the heel

and also cover the nuts, spring washers and bolt tips. |

|

|

|

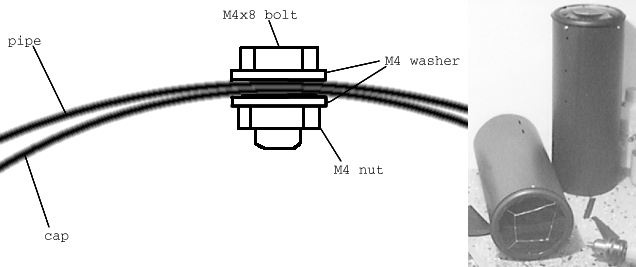

Mounting front capScrew the front cap in using 4 M4x8

bolts, 8 M4 (4.2mm) washers and 4 M4 nuts. Seal the joints from outside with

silicone sealant. Seal the gap between the pipe and the cap with silicone

sealant from outside. |

|

|

|

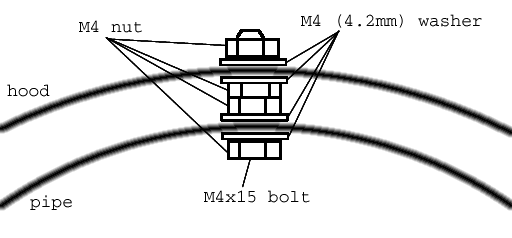

Attaching centre of the hoodMount the hood's

central two holes on two holes on the top of the pipe using 2 M4x15 bolts, 8 M4

(4.2mm) washers, and 6 M4 nuts. Tighten firmly. Seal the joints from inner

side carefully with silicone sealant. Press the hood against the pipe firmly

and drill through the remaining holes on the hood with 4.3mm

bi. |

|

|

|

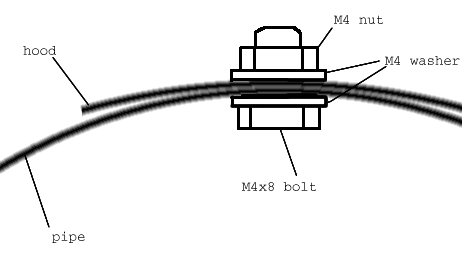

Attaching hood sidesMount the hood sides using 4 M4x8

bolts, 8 M4 (4.2mm) washers, and 4 M4 nuts. Tighten firmly. Seal the joints

both from inner and outer side with silicone sealant. Put also some sealant

between the tins before you assemble them together. |

|

|

Preparing silica gel

- Put the

silica gel into the two boxes (200g fits into two 92x67 boxes and

100g into two 67x46 boxes). Screw up using M4x25 countersink head bolts

and double M4 nut. Tighten the nuts one against the other.

- If the silicagel is not 100% dry (usually shipped in airtight

containers), put the bag into oven (at minimum heat) for two hours. Gas oven

to minimum setting, electric to 150degC. Do not use microwave oven. If you

were so stupid you bought the blue one, be sure not to do that in a kitchenware

and destroy the vessel safely after usage because it will be contaminated by

the cancerogenous dust. Store the dry silica gel boxes in airtight jars or

plastic bags.

|

|

Grinding paint off positioning-critical jointsUse emery

paper to grind off paint around the six holes on the heel. |

|

|

|

To saveSave the slide covers, 4 self-cutting

screws, and 4 M4 washers for mounting electronics inside and closing the rear

cap. The washers should be put under heads of the screws. |

|

|