|

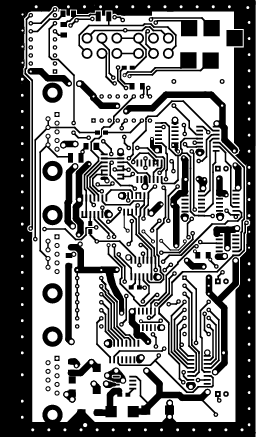

| Postscript / PDF / EPS / BIG png / Gerber RS274-X (gerbv) |

Sometimes it can come out that there's a bug in the device and you need to modify an existing device. Or someone third comes with an improvement that you would like to add. Or you may need to modify the device before you build it, because you cannot get the right part and the part you can get has different mechanical dimensions or electrical properties.

Being able to modify the device is a good thing. You don't need to spend time and money on transporting the device somewhere when you can do it yourself. You don't need to be dependent on a part which is difficult to get when you can use a replacement that differs in mechanical dimensions.

For the first kind of modification there are schematics and drawings that you can use. These are made in free software so you can install the software necessary for editing them without paying royalties. For some modules like Twister2 you even get a special chapter devoted to repairing.

For the second kind of modifications you have the printerd boards designed in the free software called PCB. Let's say you cannot get switches in the right footprint and the ones you can get cannot be inserted into the existing 12 big holes in the top of the board as you see on the left side. Then you can download PCB, and install it on your computer. Do you have an operating system where PCB doesn't run? No problem, you can download Linux for free and install it on a spare partition. Then you load the .pcb file into PCB and change sizes and positions of the holes and possibly move the traces around them a bit. You save the board into Gerber files and you are ready to send the modified version to the manufacturer.

Or what if you want to save cost on the switches altogether, when you know the Twister2 will be connected exclusively into a switch and never into a PC? Then you can easily short circuit the traces in the schematic editor and you can use the same films for soldermask and silkscreen and change only the copper layers, which saves you substantial price for film development by the manufacturer.

This wide variety of possible modifications is not possible with commercial designs or with designs where the PCBs or schematics are designed in proprietary programs. You surely don't want to buy a proprietary program just because your shop sells a bit different switches.

The situation actually already happened with crystal oscillators. The original spec of the oscillator was DIL14 and people were complaining they could get only DIL8 ones. Everyone could make a modification quite easily. It wasn't done by anyone, but it could have been done easily. Finally I added the modification into the official version so now the board supports both.

The same situation can easily happen with connectors, coils or capacitors. We attempt to design in a way which is as portable as possible, however it can happen that someone can get only an exotic version of some component.